2016 – March 23rd 〉

Expanding its Orlando Repair Station

WICHITA, Kan. (March 23, 2016) — Lee Aerospace Announces Additional Aircraft Windshield and Window Services in Florida, Georgia, and Alabama. Lyle Piland and Lorenzo Martinez join a talented and established team in Orlando. Though, they are new to the Orlando Repair Station, they are certainly not new to Lee Aerospace, nor the Lee Aerospace Aftermarket Sales and Repair Station Team. Both, Lyle and Lorenzo, having successful careers in Wichita are ready to take their years of Repair Technician knowledge to help get our southern customers back in the air. They are a wonderful addition to the Aircraft Windshield and Window Services, Certified Repair Team in Orlando and the Orlando Repair Station.

Lee Aerospace’s qualified and FAA certified technicians can inspect every window in your aircraft, and provide you with an expert, detailed evaluation on the condition of your aircraft windshield and cabin windows. Certified technicians can install new replacement windshields and windows on-site, using factory authorized equipment and adhering to OEM specifications. Lee Aerospace technicians can quickly polish, or install your new windows, to meet the demands of your schedule.

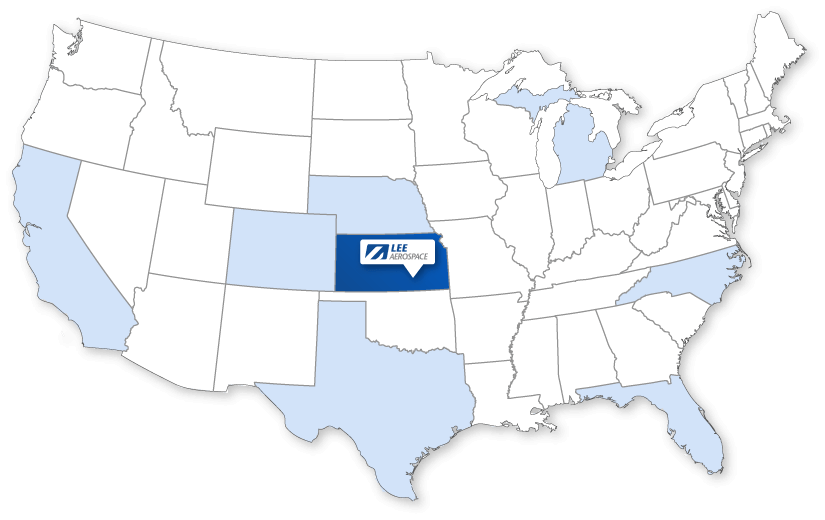

Lee Aerospace has strategically located A&P Mechanics and FAA Certified Window Technicians are the United States; California, Colorado, Florida, Kansas, Michigan, Nebraska, North Carolina, and Texas. From these locations, Lee Aerospace can quickly respond to AOG’s World-Wide. For more information on Lee Aerospace’s Repair Stations or if you would like a QUOTE please email Repairs@LeeAerospace.com or call 1-316-636-9200 / 1-316-636-9200

###

About Lee Aerospace

Lee Aerospace is Headquartered in Wichita and was founded in 1989 by owner and President Jim Lee. Starting as a small production facility, building Cabin Windows for the Boeing 737/757, Lee Aerospace has grown through the years to include advanced aerospace transparency design as well as repair and installation, aerostructure assemblies and composite manufacturing programs, for some of the largest aircraft manufacturers in the world.

Transparencies: Offering turnkey solutions from concept through production. Currently, the window OEM for major aircraft manufacturers such as Cessna, Beechcraft, Bombardier Learjet, Hawker, Honda and others. Lee Aerospace holds Parts Manufacturing Approvals (PMA) for replacement windows; windows that meet or exceed the original aircraft manufacturer’s specifications. Newest program includes the production of heated windshields. Lee Aerospace sells replacements windows direct for the following models: Beechcraft, Bombardier, Challenger, Cessna 441, Gulfstream, Falcon, Hawker, and Learjet

Services: As the industry leader in transparencies, Lee Aerospace’s qualified and FAA certified technicians can inspect every aircraft window, and provide an expert, detailed evaluation on the condition windshield and windows. Certified technicians can install new replacement windshields and windows on-site, using factory authorized equipment and adhering to OEM specifications. Lee Aerospace has a Global presence and has technicians located throughout the United States, to respond quickly to customer needs; repairing, or installing windshields and cabin windows, to meet the schedule demands.

Aerostructures: Lee Aerospace manufactures sheet metal assemblies for the most respected aircraft manufacturers in the industry. As a certified and FAA approved facility, adhering to the most stringent quality control standards throughout the organization. Its aerostructure facility is capable of building small bench top assemblies to large pressurized and non-pressurized fuselages, managing multiple programs with multiple production rates and customer requirements, delivering world-class quality.

Composites: Lee Aerospace’s Composite Manufacturing program is housed in a 40,000 square foot facility. Customers include: Boeing, Bombardier, Cessna, Gulfstream, HondaJet, Learjet and others. Its composite parts are manufactured using autoclave or oven cured prepreg or wet lay-up materials like carbon fiber, fiberglass, graphite, Kevlar and other aramid polymers. The Composite Shop uses the latest technology and equipment for the production of composite parts and control of composite time and temperature sensitive material.