At Lee Aerospace, we have over 50,000 square feet of assembly room floor and a highly trained assembly work force dedicated to aerostructures. We can assemble anything from small bench top assemblies to large assemblies. The details for these assemblies are put together using bench type tools like Assembly Jigs (AJ) up to Floor Mounted Assembly Jigs (FAJ). Our assembly techniques include installation of solid rivets, pull fasteners, tool-drilled holes, hand-drilled holes, coordinated pilot holes (ATA), close tolerance hi-lok holes, wet installed fasteners and an automated riveter.

We are qualified to assemble structural “wet” wing assemblies sealed in compliance with fuel tank requirements. We also seal pressurized fuselage sections that are required to pass leak-free aircraft pressure tests.

Quality inspection of assemblies employs a progressive buy off technique. Sub-assemblies are bought off before they are fed into larger assembly tools. Detail parts are bought off to Manufacturing drawings describing the pilot hole manufacturing plan. Our current assembly programs include:

- Wing leading edge assemblies

- Wing spar assemblies

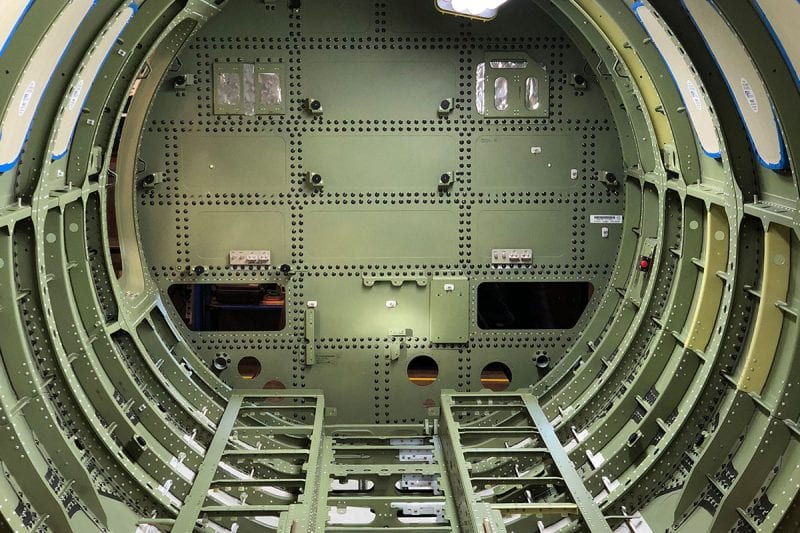

- Pressurized fuselage assemblies including AFT pressure bulkhead

- Aft tail cone assembly including engine attach and vertical fin attach fittings

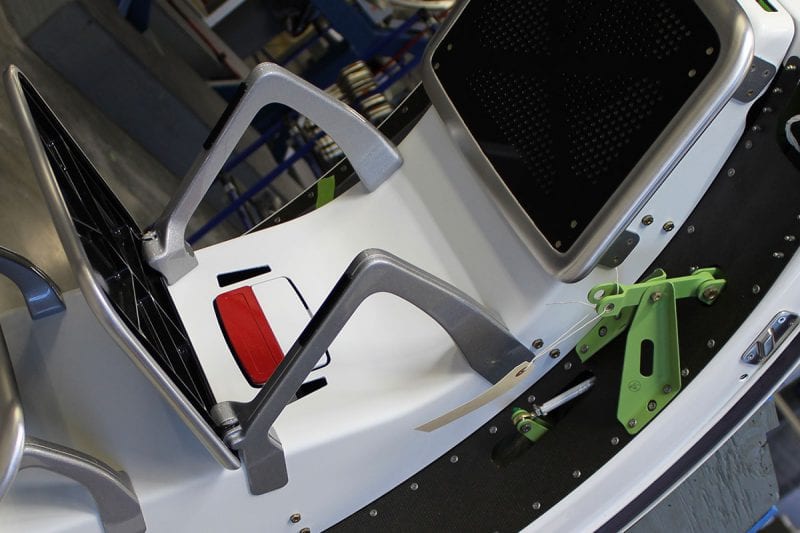

- Control wheel assemblies including wire bundle soldering and final functional testing

Aerostructure Assembly Gallery

Tail Cone Assembly

Lee Aerospace produces the aviation tail cone assembly for OEM Production. Our airframe manufacturing processes incorporate the best practices of anti-corrosion applications and lightning protection where applicable. The tail cone sections meet stringent mandated load and flight characteristics as well as contain the components that perform many roles for different airframes. The aviation tail cone assembly often houses major components of various systems including hydraulics, environmental, electrical distribution, flight controls, engine fire extinguishing and an externally serviceable toilet. A baggage compartment is also often located in the tail cone, where external access to both the equipment and the baggage area is necessary to allow maintenance through removable exterior panels, as well as baggage doors, that both meet high profile certification standards.

These aviation tail cone assembly structures are compliant in meeting energy transfer requirements through various load paths. There can also be backup structures designed as part of the metal airframe, where metal bonding techniques are used, in place of traditional assembly, to additionally lighten weight and durability as necessary. Weight can also be conserved in acceptable applications with parts made of composite materials.